Part 6. Net completed!

..at long last, everything finished and ready to use.

The final tasks were to finish turning the greenheart handle and make the ferrules which join everything together.

I had previously roughly turned the handle sections and allowed them to dry out a little before finish turning. This was quite a job to do as the lathe has only a very limited capacity. I would have liked to have made the handle as one piece but this was impossible so it was made as two, being joined together by both close-fitting ferrule and 3/8" BSF thread in the centre.

It actually ended up a bit better this way, since both sections are of differing lengths, I have the option of either a 4' handle or one with a reach of over 7'-which might be a big advantage..

In order to turn a long length, the tailstock was removed and the fixed steady set as far to the rear as possible. I turned as much as I could, constantly adjusting everything to get maximum reach, then reversed the wood and picked up where the last cut ended, with a lot of sanding down after to 'blend in'..

This will give you some idea of what was involved.

It took a long time but we ended up with a 2-piece handle tapering continuously from 1" down to 5/8" over 7'.

The 'steps' were then turned for the ferrules to fit over and some grooves for extra grip put in on the end.

When everything was sanded down, I gave both parts a thorough treatment with raw linseed oil, rubbing down vigorously between coats and finishing with Deck oil, then polishing up until dry.

Next, I made the ferrules for 1. joining the net frame to the top part of the handle and 2. to join both parts of the handle.

The top one was made from an odd piece of nickel but the remaining ones from brass.. After degreasing, I chemi-blacked all of them except the male part of the join. The nickel came out a bit blue-ish, more so than the brass..

This is how a one of the female ferrules was made:-

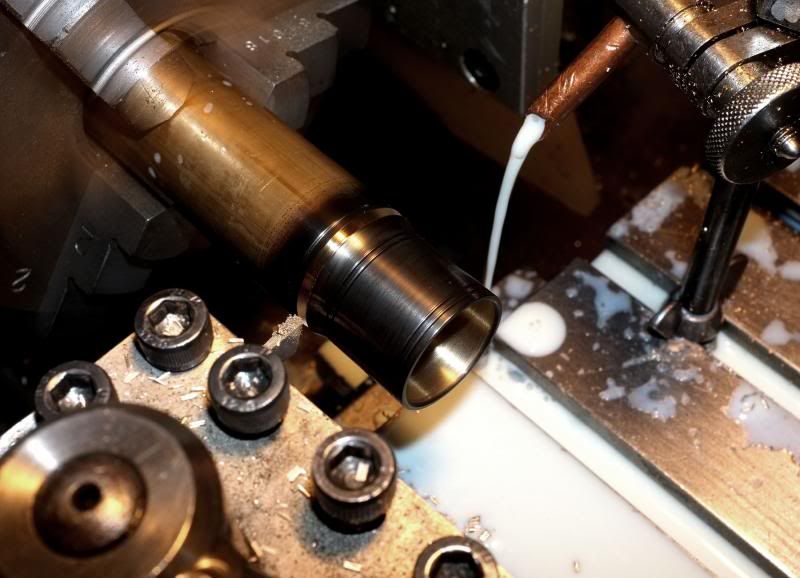

Firstly, a billet of 1" diameter brass was loaded into the chuck..

..then,it was faced off, drilled through 21/64", being the tapping size for a class 3B, 3/8" BSF thread, counter-drilled to waste away excess metal then bored to fit the male ferrule. Finally, the thread was tapped in.

It sounds complicated but it isn't really; you just work through it in a set order and the job appears in front of you!

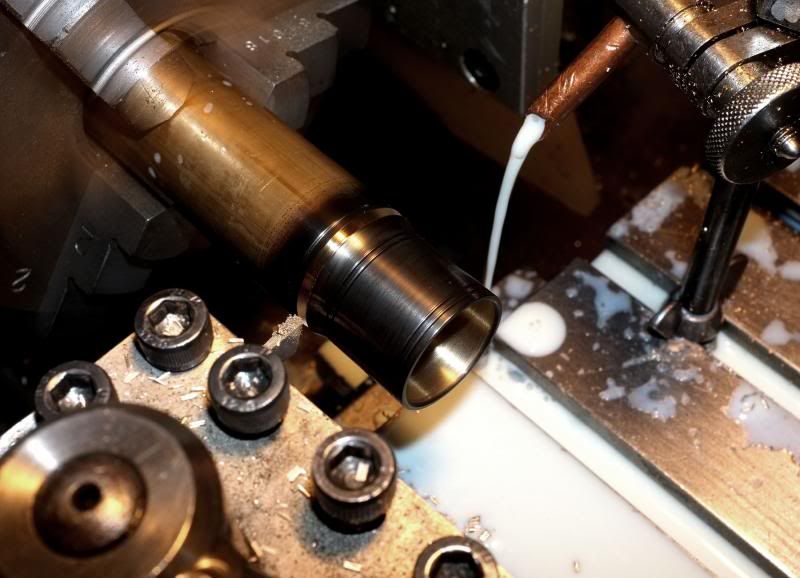

Next, the outside diameter was finished turned..

..a little blacking put on..

..and the job parted off.

Next, we made a 'button' from a piece of black delrin by facing, drilling and tapping the thread, then reversing it and mounting it on the tap and finish shaping by freehand filing, finally finishing with emery paper.

I then made some pieces of 3/8" BSF studding from brass rod, fixing a short piece in to the button and another into the joining female ferrules.

This then completed the net as such so here are a few pictures of everything.

It's obviously a bit weightier than a bamboo handle but to me, weight in a landing net is not going to be an issue. You don't have to carry it far and it's only in use for a few brief moments at a time when landing a fish!

Hope you like this as much as I have enjoyed making it......and looking forward to the new season when we can try it out!

With both handle parts joined together, ready for use..

The screw joint fitting..

The net complete.

Regards to all,

wm+